Programmatic Manage machining can make it hassle-free to change types. Also, multi-sequence machining on one device simplifies the management of the production process, lowers the volume of management staff, and might accomplish unmanned manufacturing.

The CNC method is composed of various circuit boards, Every with numerous solder joints. Any defective soldering or weak Make contact with can lead to failure.

Conserving cash is likewise obtained by retaining aspect repositioning into a minimum amount. Machining at five-axis and higher than can often be far more cost-effective on multi-faceted geometries as it gets rid of the necessity to manually reposition the component.

Getting a radical understanding of the overall performance and instructions from the CNC device Device staying used and effectively using Just about every instruction when composing system segments.

At this time, There's a diversity of people who classify as CNC device Resource operators, such as those people who are knowledgeable about machining but not with programming, newly graduated pupils who have theoretical understanding of machining and programming but lack arms-on experience, and others who may have no prior exposure to machining or programming.

Capability to modify machining parts by simply altering the NC plan, preserving manufacturing planning time

Parameter Check out the equipment details from the NC equipment Instrument is a crucial parameter more info obtained through a series of tests and adjustments, which happens to be the assurance of the conventional Procedure of the device Software.

It’s imperative that you Observe that the choice of a specific CNC machine Instrument will fluctuate based on the manufacturer, measurement, and configuration.

When manually loading the Instrument in the Resource journal, ensure it can be securely installed, and Look at the lock to the tool foundation to make certain it really is reputable.

This machining technique is pretty straightforward and can produce merchandise with an easy framework. Having said that, it is not appropriate for machining complex geometries or goods with intricate factors.

Have you at any time questioned how CNC machines form our globe? These adaptable resources revolutionize manufacturing, handling duties from simple drilling to complex milling. In the following paragraphs, we’ll take a look at the various…

Can develop most parts with basic geometries. Higher precision & tight tolerances. Resource accessibility & workholding design constraints use. Handbook repositioning in the workpiece lowers the achievable precision.

The spindle axis of the vertical machining center is about perpendicular for the workbench and is especially appropriate for processing sophisticated parts such as plates, discs, molds, and smaller shells.

As Parsons’ business acquired identified as on for making A growing number of advanced plane parts, they turned to computational strategies and cnc machined parts to accomplish their wished-for styles.

Danny Tamberelli Then & Now!

Danny Tamberelli Then & Now! Haley Joel Osment Then & Now!

Haley Joel Osment Then & Now! Alicia Silverstone Then & Now!

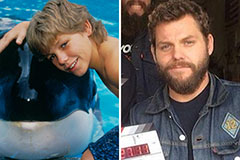

Alicia Silverstone Then & Now! Jason J. Richter Then & Now!

Jason J. Richter Then & Now! Danny Pintauro Then & Now!

Danny Pintauro Then & Now!